EU regulation 2019/1781 lays down eco-design directives for electric motors and variable speed drives. Effective October 2019, this regulation defines labeling guidelines and benchmarks for electric motor efficiency.

EU regulation 2019/1781 lays down eco-design directives for electric motors and variable speed drives. Effective October 2019, this regulation defines labeling guidelines and benchmarks for electric motor efficiency.

International trade in electric motors occurs at high volume, with global exchanges in 2020 clearing over USD 100B worth of volume. Electric motors and variable speed drives (VSDs) occupy important roles across a range of different marketplaces, and their applications vary widely. Therefore, a large portion of (EU) 2019/1781 is devoted to building a precise definition of motors that fall under its statutes, as well as those motors that are specifically excluded from the definition.

Additionally, the regulation provides guidelines for the eco-design of electric motors. These points are concerned with the construction, operation, and output of motors and VSDs. Some of these requirements are listed as a range of values, due to the significant variabilities in the design and application of motors.

Electric Motors | Variable Speed Drives |

|---|---|

|

|

Clearly, electric motors (as a class of products) are broad and complicated to define. Devices may be designed for specific applications, for use in extreme operating conditions, or require nonstandard sizes or shapes. Importantly, many of these specialized motors and VSDs may be exempt from regulation or else governed by a separate set of guidelines.

These devices are likewise governed according to their construction and their application. Note that most exemptions are designed for motors fully built into other products, or those designed to accomplish very specific and intensive work. Therefore, product specifications might include a seamless build or exceptional durability, such that the motor becomes an integral part of the parent product. In this case, the scope of product environmental regulation shifts to the product as a whole.

Electric Motors | Variable Speed Drives |

|---|---|

that are exempt from 2019/1781 section 1, and points (1), (2), (5) to (11), and (13) of section 2 of Annex I: | that are exempt from 2019/1781 section 3, and points (1), (2), and (5) to (10) of section 4 of Annex I: |

|

|

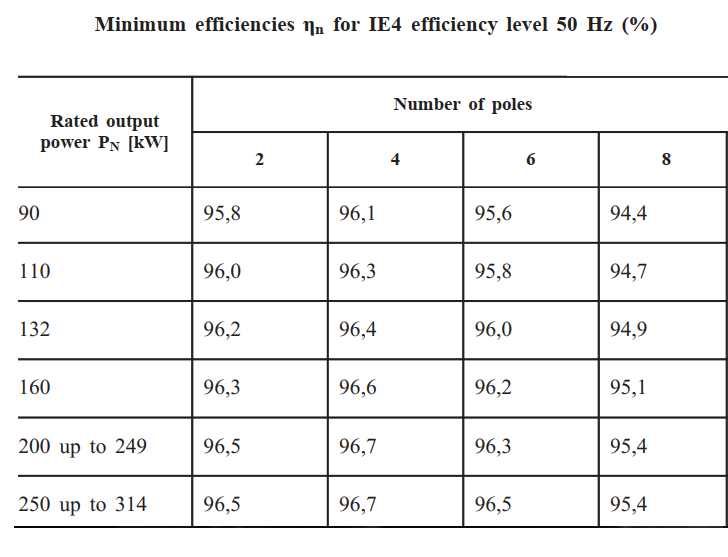

After confirming that a motor falls under eco-design regulations, it receives a corresponding minimum energy efficiency value. This parameter depends on the motor’s construction, operating frequency, rated voltage, and output power. The regulation document provides a selection of standard rated power values and ranges; depending on the number of poles in the motor, the regulation assigns a value indicating a mandatory minimum performance.

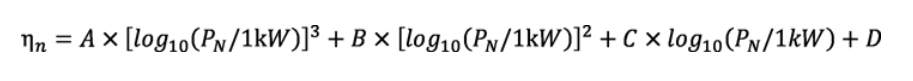

Finally, the resulting values are tabulated according to IEC efficiency classes for 50 and 60 Hz operation. Motors with nonstandard power ratings can have their classes and minimum efficiencies calculated, rather than assigned by lookup. Be aware that the rules applied to such motors depend on their operating frequencies: 60 Hz motors use the efficiency of the next highest or next lowest standard power rating (whichever is closer), while 50 Hz motors can use the formula

Other important values, like loss parameters and interpolation coefficients, are assigned to motors according to their construction and power transfer characteristics.

VSDs follow a classification process that is much like electric motors, although they are given their own set of specific guidelines and key parameters.

Let us consider a case study: a modern industrial motor targeted at large freight hovercrafts is designed and fabricated in the Czech Republic. It is replaceable, follows a six-pole “high torque, low rpm” design methodology, and has a maximum rated power of 75 kW.

Since the motor is destined for the North American market, it is intended to operate at 60 Hz. Together, all of these parameters designate the motor at an IEC efficiency class of IE3 at the lowest.

Therefore, 2019/1781 stipulates a minimum efficiency of 95.0% at full operation (Annex I, Table 3b).

In addition, motors are frequently used to drive fans for cooling or ventilation purposes.Consequently, a fan driven by an electric motor that uses an input power between 0.125 and 500 kW may be subject to additional ecodesign regulations under (EU) No 327/2011.

Any fans integrated into: | Any fans designed to be operated: |

|---|---|

|

|

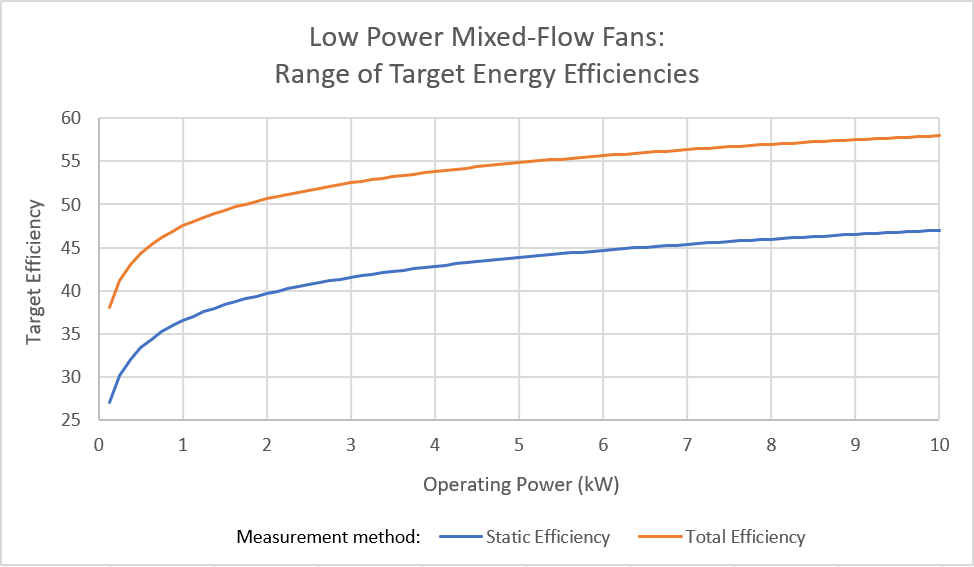

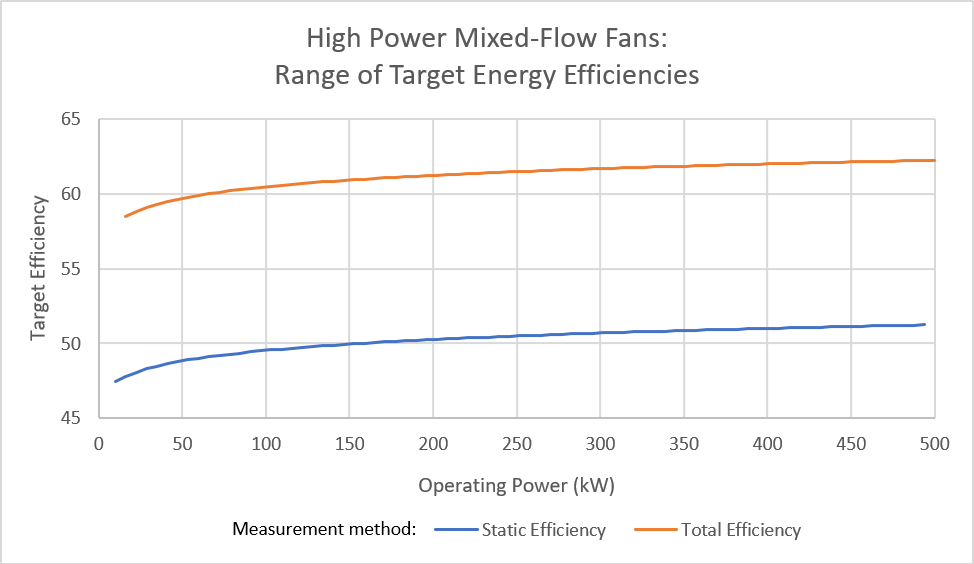

Fortunately, fans are classified similarly to the motors that drive their motion. That is, they must uphold a minimum performance that depends on their construction, range of rated power, and any ducts or fittings attached to the fan during operation. In almost all cases, a fan’s target energy efficiency is expected to follow a logarithmic relationship with its output power P, via

η = A ∙ ln(P) – B + N

source: (EU) No 327/2011 Annex I Table 1

where the parameters A and B depend on the type of fan and its configuration. For example, a mixed-flow fan has the following energy efficiency profiles under low- and high-power operating modes:

After ensuring compliance with ecodesign regulations, suppliers may also need to consider other environmental requirements. Additional legislation may require further groundwork, depending on a product’s intended market. For example, the following regulations also apply in the EU and elsewhere:

If you need help navigating eco-design regulations for an electric motor or VSD you are developing, our experts at Enviropass can offer step-by-step guidance for all your environmental needs.