The Gist of IEC 62321

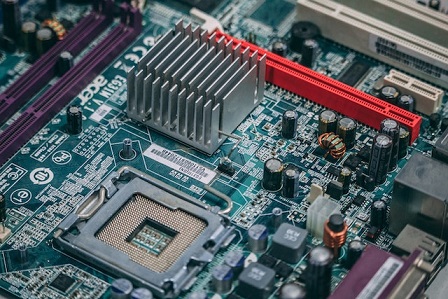

In chemistry testing of electronics, chemists define a sample as a substance made of polymers, metals, or plastic materials. It is a representative specimen that undergoes various tests and evaluations to gather information about its chemical composition. These samples can exist in diverse forms, such as powders, liquids, solids, or complex structures like electronic components.

IEC 62321 is a standard published by the International Electrotechnical Commission titled: Determination of certain substances in electrotechnical products. Its objective is to detail the best common practices for testing electrical and electronic equipment (EEE).

IEC 62321 is made of a dozen of parts, including:

- Part 1 – Introduction and overview

- Part 2 – Disassembly, disjointment and mechanical sample preparation

- Part 6 – Polybrominated biphenyls and polybrominated diphenyl ethers in polymers by gas chromatography- mass spectrometry (GC-MS)

- Part 8 – Phthalates in polymers by gas chromatography-mass spectrometry (GC-MS), gas chromatography-mass spectrometry using a pyrolyzer/thermal desorption accessory (Py/TD-GC-MS)

This compilation of standards primarily serves RoHS (Restriction of Hazardous Substances) assessments of EEE. To get familiar with the entire RoHS testing process, let us discuss IEC 62321-1 – introduction and overview.