Legislation and standards restrict more and more hazardous substances found in electrical and electronic equipment (EEE). The most prominent regulation is certainly the EU RoHS – Restriction of the use of certain Hazardous Substances, which requires to manufacturers a RoHS procedure.

Those restrictions apply either to products or to production activities. They may involve product labeling such as the CE marking per EU RoHS, as well as different product assessments, subscriptions to agencies, specific statements, or declarations of conformity (DoC).

When exporting or placing finished goods into a specific market, the manufacturers must demonstrate that their in-scope products meet the applicable local substance restrictions. Precisely on EU RoHS, the article 7 paragraph (b) of the Directive 2011/65/EU of the European Parliament and of the Council requires manufacturers to:

”draw up the required technical documentation and carry out the internal production control procedure (…) or have it carried out.”

The goal of a procedure is to describe the environmental compliance management system of products, to show due diligence, and to declare compliance against applicable product environmental laws, like Eu RoHS. Any manufacturer introducing EEE in Europe should draft such a procedure, regardless of the ‘made in’ and country of origin.

As a company, you should carry out risk analyses and determine the essential requirements applicable to your EEE products, such as RoHS, REACH SVHC, WEEE, California Proposition 65, and others. Your product RoHS technical File should record and include such risk analysis. It must be continuously updated over time and periodically revisited. Here are five steps that an EU RoHS technical file should encompass.

Before assessing a product, the first step is to find out what the rules are. Consequently, the manufacturer must find the most recent versions of environment-related regulations worldwide and standards that apply to the EEE manufacturing industry. As you can imagine, these regulations evolve and you need to keep abreast of product environmental compliance.

Different resources are available, such as the Enviropass’ LinkedIn page and Environmental Compliance Newsletter, specialized associations (e.g. IPC), inter-governmental bodies (e.g. IEC), supranational bodies (e.g. European Union ECHA), national, federal (e.g. EPA). You can also take a course, like the three modules online Introduction to Product Environmental Compliance.

Once you know what the potentially applicable product environmental requirements are, then it is recommended to apply a regulatory risk assessment and prioritize the standards and regulations of interest. There are many ways of performing such an assessment. For example, you can determine what is riskier in terms of product characteristics, markets, consumers, legal obligations, share-holders, etc. Your procedure should reveal your corporate choices and a specific internal form should be drafted and reflect what requirements are low medium and high risk.

As you can imagine, ”high risk” requirements will have to be prioritized. A summary should explain what is at stake in detail, if necessary, article per article, for every type of your in-scope EEE. The EU RoHS requirements are usually considered as high risk if we compare them to voluntary standards. Various countries, with national deviations, have also enacted RoHS-like regulations, such as China RoHS, Taiwan RoHS, the United Arab Emirates UAE RoHS, Russia RoHS, etc.

According to EU RoHS, the manufacturer must conduct the applicable conformity assessments of its products or have them carried out. But in any case, the manufacturer is responsible for the conformity of its products.

Enviropass is here to help you assess your products against RoHS, REACH SVHC and Annex XVII, California Prop. 65, Persistent Organic Pollutants POP, and any other product environmental compliance requirements.

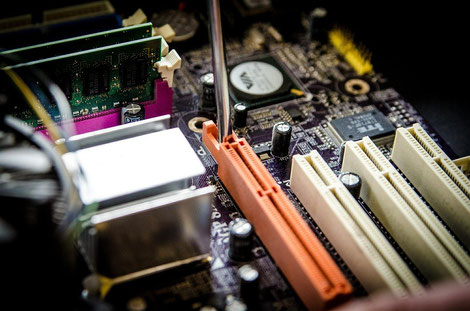

We highly recommend the documentary approach according to the IEC 63000 standard to perform the RoHS assessment of a complex product. This standard, for ‘technical documentation for the assessment of electrical and electronic products with respect to the restriction of hazardous substances‘ is well recognized by both the industry and enforcement authorities. It will help you save costs while giving reliable reports. Indeed, the idea here is to work with your supply chain, to gather as much information as possible, and perform risk assessments. Try not to do chemical analytical testing.

The conformity assessment is conducted by reviewing the documentation as collected from your providers, for every EEE that must be compatible with any RoHS jurisdictions, worldwide.

Every component and material included in the parts list (or Bill of Materials- BOM) of a product must be assessed at the manufacturer’s source level.

Per IEC 63000, you must consider the likelihood that a material contains a restricted substance and the trustworthiness of your suppliers. To do so, various types of documents can be accepted as proof of compliance, such as certificates of compliance, declarations, filled-in forms, drawing sheets, specifications, etc. It depends on the component or the material that is being assessed. What you ideally want is that all your suppliers commit to RoHS compliance.

In any case, you must make sure that your supporting documentation will enable you to determine the minimum of RoHS information, such as:

In doing so, feel free to use the free Enviropass Product Environmental Compliance (EPEC) form for your RoHS compliance inquiries. This form is updated every time a covered regulation is amended.

Your RoHS assessments must be recorded and include all the documents used as evidence. The RoHS compliance system must be maintained over time, and be consistent with your product modifications, redesigns as well as the RoHS regulation updates.

A product can only be assessed as compliant if all the components and materials are found compliant. If the conclusion of a product assessment shows compliance, then the manufacturer can produce a Declaration of Conformity, also known under the acronym ‘DoC’. The RoHS DoC must follow the EU RoHS Annex VI of Directive 2011/65/EU, and include:

Such a RoHS declaration is part of the CE DoC, which is a folder containing all the DoCs associated with one product.

Finally, the DoC must be made available to the surveillance authority upon request. In any case, when a surveillance authority, an importer, or a customer requests a DoC, the manufacturer should provide its up-to-date version, at the time the electronic product was placed into the EU market.

Every product with a complete technical file and valid DoCs must bear relevant conformity markings according to the risk analysis and product requirements. The marking for a RoHS compliant product is the CE marking. No other marking such as a lead-free, or a RoHS label is permitted, because it may mislead the customer.

Note that the CE marking obligations also cover other directives than the EU RoHS, such as electrical safety requirements. The ‘blue guide on the implementation of EU products rules‘ gives details on how to fully comply with the CE marking requirements.

In a nutshell, the manufacturer must explain the following four actions:

According to article 7 paragraph (b) of the Europe RoHS Directive 2011/65/EU of the European Parliament and of the Council, manufacturers must:

”(…) ensure that procedures are in place for series production to remain in conformity. Changes in product design or characteristics and changes in the harmonised standards or in technical specifications by reference to which conformity of EEE is declared shall be adequately taken into account.”

The product technical file is not static. You should undertake the RoHS testing process anytime a product’s technical file must be updated. It must be updated, whenever:

The product RoHS compliance is likely to change. For example, if an exemption is removed per a RoHS amendment, a new assessment should be conducted. Then, the previous declaration of compliance (DoC) is obsoleted and replaced by the latest version of the DoC, which becomes valid on the date of its signature.

When, one manufacturer source does not provide evidence of compliance for a specific component, then the whole part is assessed as non-compliant. There is no de minimis tolerance threshold here. A component can only be evaluated as compliant if all of its manufacturer sources are found compliant. Also, if a manufacturer source benefits from an exemption, the entire part is also assessed as compliant under that same exemption.

Your RoHS procedure should explain any further actions when a tested product is not EU RoHS compliant. Here are two examples of corrective actions your procedure can detail:

At the last resort, if you decide to undertake analytical RoHS testing on homogeneous material samples, then you should implement a testing plan. In the testing plan, you will determine the type, the number of samples, and the periodicity of the analytical RoHS testing. This undertaking can reveal costly in terms of energy, time, and money. It is recommended to ponder all the options before considering such a testing campaign.

This will certainly happen. Imagine the technical documentation you have gathered for a specific parts list shows ambiguous or contradicting information. For instance, you may have collected:

If the supplier is unable to provide the remaining missing information, then corrective actions, as described above, must be performed.

This is a key concept when it comes to drafting a RoHS procedure. For example, the RoHS procedure itself will be revised and previous versions should be archived.

Every finished good must bear:

According to the EU RoHS directive 2011/65/EU, every element of the technical files should be kept for at least ten years after the last item of a product model was placed on the market. The procedure should reflect this period. Therefore, the manufacturer must keep a ten years record of:

Every non-conforming EEE and product recall must be registered internally as well. However, if you apply a robust RoHS procedure, product recalls because of a non-RoHS compliant product, should not happen.

Need help with your product environmental compliance or your RoHS procedure? Contact Enviropass!