Hi! Here is an example of how you can compile your RoHS technical file by gathering manufacturers’ declarations of conformity. It is a four-step process. Let’s get started.

Hi! Here is an example of how you can compile your RoHS technical file by gathering manufacturers’ declarations of conformity. It is a four-step process. Let’s get started.

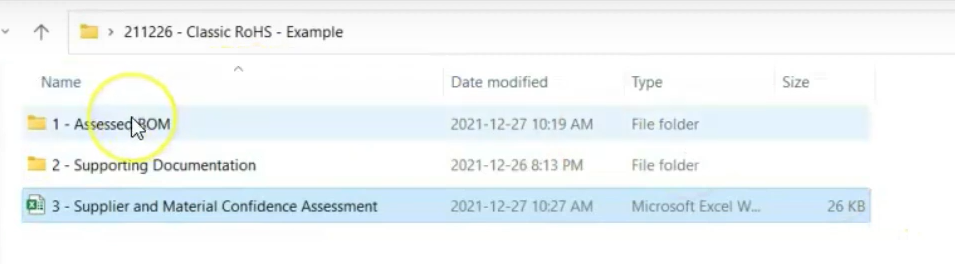

First of all, you receive a BOM (or a bill of material) for a specific product. Let’s open it!

That will be here in the first file.

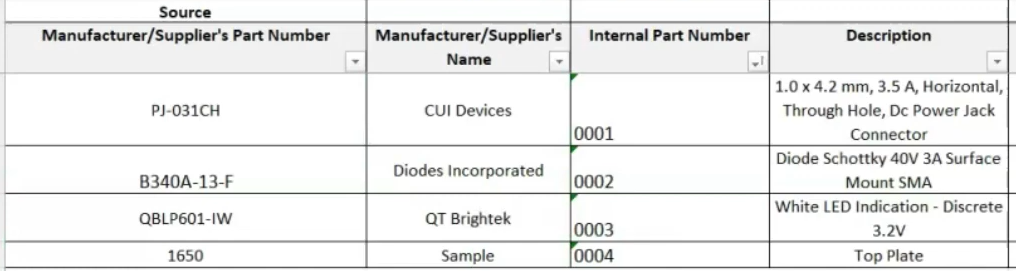

You see here: it shows my BOM. Let’s see how many parts we have there. It’s an example. It will be very simple. BOMs can be much bigger than this one. You see, here, are four parts. So what you need to do is to compile these parts into folder number three, which is the supplier and material confidence assessment.

If you open it, you will see the first three columns which are the ones that you to fill in. The information is:

So, let’s do that!

Okay, so it’s done now!

Now, we can move on to step two. And don’t forget to save. Now, we can do our first RoHS research!

How do we do it? It’s very simple! Let’s take the first part: part number zero zero zero one. And, we’re going on these suppliers’ websites.

So, let’s do a Google search with this company: CUI! This is just an example. Then, you will search, maybe, the part number. Then, let’s do the manufacturer’s part number and the company’s name is appearing. You see, here is the company’s website. It’s always better to have the actual company (manufacturer) than a distributor. So, let’s go to the manufacturer’s website and search. You can look at the company’s information if you have any environmental compliance details. They could be in About us. They could be elsewhere. You can look at the very bottom of the website. You see here: Quality Center. You may find good information. You see material compliance, products life cycle that could help.

If you look in more details here, you see there is an email address. It’s always interesting to have. And a statement!

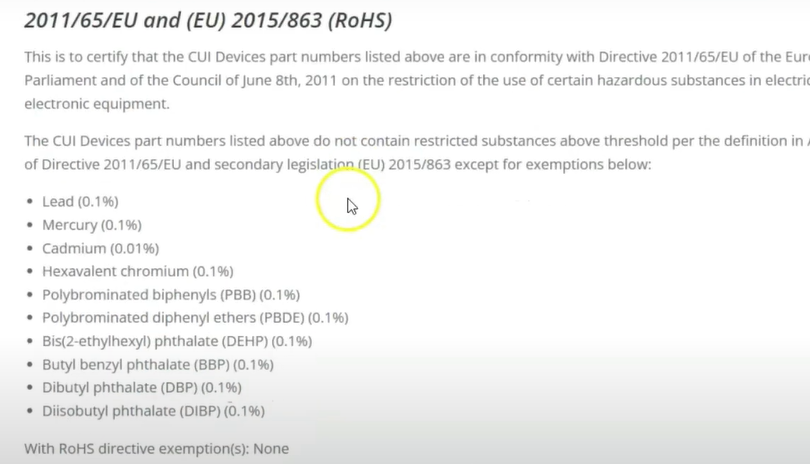

This document is perfect. Therefore, you need to fill in folder number three. Here, you know, YES, it is RoHS compliant, in Column F. You will fill in compliance with EU RoHS: YES. And NO, there are no declared exemptions. So here, you would enter NO. Otherwise, that would be the exemption number. You will need to verify if the exemption is still valid.

Don’t forget to save it, and then you also need to save this document. Print it and, you would save it. Create the supplier’s name. Create the folder inside of folder 2 Supporting documentation. Then, you give a name. It could be the part number or any. The name shouldn’t be too long, no longer than one line. It could be the name you prefer. You need to keep this

evidence as proof, a demonstration that the part is indeed RoHS compliant. So you finished the research for the first part!

Let’s try the same exercise for the second part number. Do we have anything more accurate than just, you know, this logo? We don’t know what it is about. Let’s go under diodes.com. You can use different keywords. For example, RoHS is a good keyword. Let’s try that! We will find a statement. Part Number is another very good keyword. Oh, maybe we found something here. Let’s try that one. Oh, there is a whole list.

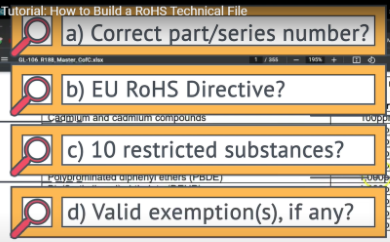

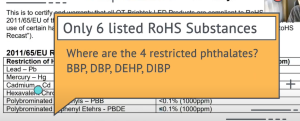

If you zoom in a little bit, you can read and recognize the directive: RoHS 2011/65/EU, and the amendment 2015/863, for the phthalates. That’s useful! You also even have a list of restricted substances.

Now, you need to remember the four pieces of information you need to find out:

Yeah! The part contains lead. There is an EU RoHS exemption. So, the part may be compliant under exemption 7A. Let’s save this document.

Now, we need to verify if exemption 7A is still valid because RoHS exemptions have expiring dates. They can have expired. It’s not obvious. We don’t necessarily know. On getenviropass.com, under Substances Control / RoHS / Europe RoHS. At the very top of this page, you will see the list of exemptions. Let’s search exemption 7A. Where is it? It’s here! Right here!

So you can list it. Declare here: YES, the part is RoHS compliant, and there is a valid exemption, which is 7A. So you will write 7A. Let’s take the most simple way of declaring the exemptions. Everything’s in capital letters.

Let’s now take the example of the third part: zero zero zero three: the QT Brightek part. Let’s do the same exercise.

Here, it only says RoHS compliant on the datasheet. Usually, datasheets are not comprehensive enough. And you see this RoHS logo. It doesn’t say much.

But we can still archive it. It’s better than nothing. Thus, I would save it in folder number two. Document it. So in your file number three of the excel spreadsheet. Here, you will write something in the comments. And you would send an email or an online request to this manufacturer. Use our Enviropass Product Environmental Compliance (EPEC) form. It’s free. We keep it up to date. You click on download.

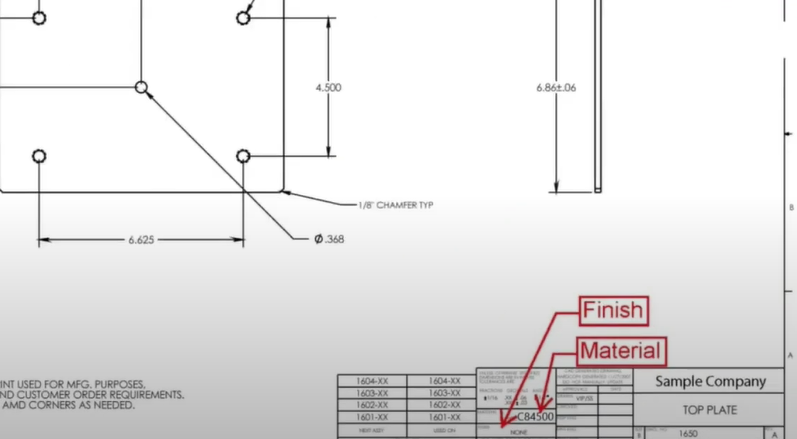

Let’s look at the fourth part: the top plate. There is a part number here. And this one is a custom part. It’s often a mechanical part. And on the, drawing you may have the specifications of the materials and the finishes. So, it’s very interesting for us to have that because if we do have the specifications, the material breakdown, we will be able to verify compliance. It must cover every homogeneous material, including the material itself and the finish: everything that is part of the product.

Here is the drawing sheet, or the technical drawing, that we’ve received for this part. You see, here: top plate.

The same rules apply. You need to make sure we’re talking about the same part. You see, here, there is the part number. If we look at these specifications, you see, here, there is a material reference: C84500. And there is no finish. So no finish, we don’t have to worry about finishes. And the material, we need to verify what is the chemical composition of this material, C84500.

Then, let’s look at it. You see, there is some literature, some information that you would find online. Here, the chemical composition. You see, it shows a 7% t lead. It’s a copper alloy. It is above the general threshold of 0.1%.

Now, it may be under an exemption. You will find there is one exemption for copper alloys. It is exemption 6C here. However, a 4% lead is accepted. Here, you have a 7% lead.

Let’s search C84500. You see, it’s here. It’s listed on this blog page, in table 4: Examples of copper alloys and their compliance.

What do they say? They say: concentration is above 4% for lead. And it’s tagged as a non-compliant alloy.

You need to report that as well under your file number 3 and you’ll write NO, it’s not RoHS compliant. And NO, there is no exemption for it. So, you write NO.

How do you document it? You would save that technical document.

Step three: this step applies once you’ve achieved steps one and two for the parts without sufficient online information, like part 3. You must send a request to the supplier.

Then, you would send all of your emails to the suppliers with missing information for their parts.

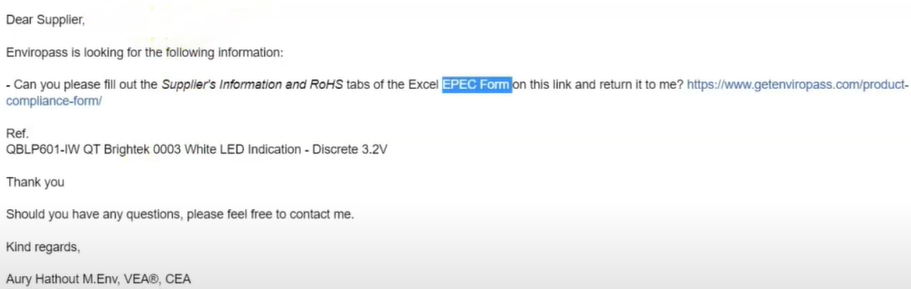

Here is an example of an email you can submit to manufacturers that don’t show enough RoHS information on their website, like the example we had.

And you would say:

Dear supplier, Enviropass (or your company’s name) is looking for the following information: Can you please fill out the, etc.

And you give the right tabs from the EPEC form: the Supplier Information and RoHS tabs. You give the link to make it clear for the supplier, and you give all of their part numbers that don’t have sufficient RoHS information.

Then step number four is a weekly follow-up by emails. You can

even call suppliers just to:

And you follow up with them. You will find any relevant document or communication.

I hope you’ve found this tutorial useful. Subscribe to the Enviropass Youtube channel to get more tips on product

environmental compliance!